Product Description

I. Product Overview

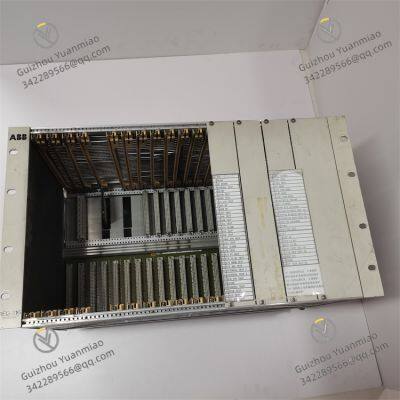

ABB 216MB66 HESG324510M1 is a device that plays an important role in the field of industrial electrical engineering. In terms of its application, it often serves as a key component in electrical systems, used to build a stable and efficient electrical connection architecture. It plays an indispensable role in the construction of complex industrial automated production lines and various types of electrical control cabinets.

The shell of the product is made of sturdy metal or high-performance engineering plastics, which enables it to have excellent protective performance in industrial environments. Whether facing dusty factory workshops, operating areas with the risk of slight collisions, or special industrial scenarios with some corrosive substances, it can effectively protect the internal precision circuit structures and electronic components, ensuring that the product can operate stably for a long time under harsh working conditions and providing a solid guarantee for the continuity of industrial production.

II. Performance Characteristics

(1) Electrical Connection Performance

Efficient current transmission: 216MB66 HESG324510M1 has good current-carrying capacity. Although the specific current-carrying value is not specified in the existing materials, it can be inferred from its wide application in industrial scenarios that it can meet the power transmission needs of common industrial equipment. In automated production lines, the stable operation of many equipment such as motors, sensors, and actuators relies on reliable power supply. This product can efficiently transmit power from the power source to various equipment, ensuring the normal operation of the equipment and avoiding equipment failures or unstable operation caused by poor power transmission.

Low-resistance connection: The product is designed to reduce the resistance of electrical connections, thereby reducing energy loss during power transmission. The low-resistance characteristic not only improves energy utilization efficiency but also effectively avoids excessive heat generation due to excessive resistance, thereby ensuring the safety and stability of the equipment. In some industrial fields with high requirements for energy efficiency, such as the power supply system of data centers, the advantage of low-resistance connection is particularly obvious, which can save a lot of energy costs for enterprises.

(2) Compatibility and Scalability

Wide compatibility: This product demonstrates excellent compatibility and can work in coordination with various electrical equipment under ABB and industrial equipment of different brands. In a large industrial project, there may be controllers, drives, sensors, and other equipment from different manufacturers at the same time. With its strong compatibility, 216MB66 HESG324510M1 can easily realize electrical connections with these equipment, build a complete industrial electrical system, break the compatibility barriers between equipment, and promote the efficient operation of the entire industrial system.

Flexible scalability: With the development of industrial enterprises and the expansion of production scale, higher requirements are put forward for the scalability of electrical systems. 216MB66 HESG324510M1 has fully considered this in its design and is equipped with flexible expansion interfaces and module designs. When enterprises upgrade equipment or add new production links in the later stage, they can conveniently expand the existing electrical system by adding relevant expansion modules without large-scale replacement of the entire electrical connection architecture, which greatly reduces the upgrade cost and time cost for enterprises.

(3) Reliability and Stability

Durable design: The product adopts a durable design concept. The internal circuit layout is reasonable, and the electronic components have undergone strict screening and testing to ensure that they are not prone to failures during long-term use. In industrial production, equipment often needs to run continuously for months or even years. With its reliable design, 216MB66 HESG324510M1 can maintain stable performance under long-term high-load operation, providing strong support for the continuity of industrial production.

Protective performance: In addition to the good physical protection performance of the shell, the product may also adopt various protective measures in the circuit design, such as overvoltage protection, overcurrent protection, short-circuit protection, etc. In industrial environments, power fluctuations and electrical faults often occur. These protective measures can respond in time to protect the equipment from damage caused by abnormal electrical conditions, ensuring that the equipment can operate safely and stably in complex and changeable electrical environments.

III. Application Scenarios

(1) Automated Production Lines in Manufacturing Industry

In the automated production lines of the manufacturing industry, 216MB66 HESG324510M1 plays a key role in electrical connection. Taking automobile manufacturing as an example, various links in the production line such as stamping, welding, painting, and final assembly involve a large number of automated equipment, such as stamping machines, welding robots, automatic painting equipment, and automated conveyor lines. These equipment need stable power supply and reliable electrical connections to work together. 216MB66 HESG324510M1 can orderly connect the electrical lines of different equipment, ensuring the stability of power transmission and the accuracy of signal transmission. When a welding robot is working, it needs precise control signals to complete complex welding actions and stable power supply to drive the motor. 216MB66 HESG324510M1 can provide reliable electrical connections for it, ensuring the efficient and accurate progress of welding work, thereby improving the quality and efficiency of automobile production.

(2) Industrial Electrical Control Cabinets

In industrial electrical control cabinets, 216MB66 HESG324510M1 is an important part of building the internal electrical connection network. Electrical control cabinets usually integrate various control components, switches, relays, power modules, etc. These components need to realize communication and cooperative work through reasonable electrical connections. 216MB66 HESG324510M1 can connect different electrical components according to design requirements to realize power distribution, signal transmission, and the issuance of control commands. In an electrical control cabinet used to control an industrial production line, the electrical lines of the controller and various actuators are connected through 216MB66 HESG324510M1, enabling operators to remotely monitor and control the equipment on the production line through the controller, ensuring the stable operation of the production line.

(3) Electrical Systems in the Energy Industry

In the energy industry, such as power plants and substations, 216MB66 HESG324510M1 also has a wide range of applications. In power plants, reliable electrical components are needed for the connection from power generation equipment to transmission lines and the electrical connection of various auxiliary equipment. This product can meet the high reliability requirements of power plants for electrical connections, ensuring that power can be transmitted and distributed safely and stably in high-voltage and high-current working environments. In substations, it is used to connect different electrical equipment to realize functions such as voltage transformation, power distribution, and monitoring protection. Since the energy industry has extremely high requirements for the stability and reliability of electrical systems, any electrical fault may lead to serious consequences such as large-area power outages. With its excellent performance, 216MB66 HESG324510M1 provides an important guarantee for the stable operation of electrical systems in the energy industry.

IV. Installation and Maintenance

(1) Installation Steps

Preparation before installation: Before installing 216MB66 HESG324510M1, first carefully check whether the product's appearance is damaged, deformed, or has missing parts. At the same time, compare with the product packing list, carefully check whether the product model, specifications, and the number of accessories are accurate to avoid affecting the installation progress due to incomplete accessories or inconsistent models. In addition, it is necessary to confirm that the installation environment meets the requirements, ensuring that the installation location is dry, well-ventilated, away from strong electromagnetic interference sources and corrosive substances, and that the ambient temperature and humidity are within the range specified by the product. At the installation site, prepare necessary installation tools such as screwdrivers, wrenches, wire crimpers, etc., and ensure that the tools are in good condition and meet the accuracy standards.

Electrical connection operation: Carry out electrical connection operations in strict accordance with the electrical installation drawings to ensure accurate and firm wiring. During the connection process, pay attention to distinguishing the functions of different terminals to avoid electrical faults caused by wrong wiring. For the connection of power lines, ensure that the wire diameter meets the current-carrying requirements of the equipment, and the wiring is firm and reliable to prevent heating or even fire due to poor contact. When connecting signal lines, pay attention to the correct connection of shielded wires to reduce the impact of electromagnetic interference on signal transmission. For some special interfaces, such as optical fiber interfaces or high-speed data interfaces, be extra careful during connection, operate in accordance with the operating procedures to avoid damaging the interface or affecting the signal transmission quality. After the connection is completed, use professional electrical testing tools to test the conductivity and insulation performance of the connected lines to ensure the reliability of the electrical connection.

Equipment fixing and installation: According to the installation requirements of the equipment, accurately install 216MB66 HESG324510M1 at the predetermined position. During the installation process, be careful to avoid collision or vibration to the equipment to prevent damage to internal components. If the equipment needs to be installed in a cabinet, reasonably plan the installation position to ensure that there is enough space around the equipment for heat dissipation and maintenance. Use appropriate mounting brackets and fixing bolts to firmly fix the equipment in the installation position to ensure that the equipment will not shake or shift during operation. When fixing the equipment, tighten the bolts according to the specified torque to avoid poor contact of the equipment or safety accidents caused by loose bolts. After the installation is completed, check the installation status of the equipment again to ensure that the equipment is installed firmly and in the correct position.

Bently 323174-01 Emergency Shutdown Device

Bently 147663-01 VGA Display I/O Module

ABB PPD513A-23-111615 magnetic excitation controller

TRICONEX Safety Instrumented System (SIS) 4351B control module

Bentley Nevada 3500/22M Transient data interface module

Bently Nevada 3500/15-05-05-00 power module

Triconex 3009 processor module

ABB GFD563A102 3BHE046836R0102 Excitation Convection Interface Module

ABB PPD117A3011 3BHE030410R3011 Excitation Controller

ABB PCD231B101 3BHE025541R0101 Excitation Unit Controller

ABB 5SHY3545L0010 3BHE009681R0101 High-Voltage Thyristor Module

ABB PCD230A 3BHE022291R0101 Controller Module

ABB 5SHY3545L0009 3BHB013085R0001 IGBT Module

Bently Nevada 3500/25 enhanced key phase module

Bently Nevada 3500/32 4-channel relay module

ABB PCD232A 3BHE022293R0101 Exciter Control Module

Bently Nevada 3500 monitoring system series modules

Bently Nevada 3500/33 relay module

ABB PCD235A101 3BHE032025R0101 Excitation Control Module

ABB PCD235C101 3BHE057901R0101 Excitation Unit Controller

Bently Nevada 3500/34 Triple redundant relay module

ABB PCD530A102 3BHE041343R0102 Controller

ABB PPD113B01-10-150000 3BHR023784R1023 Controller Module

ABB PPD512A10-150000 3BHE040375R1023 Excitation Controller

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.